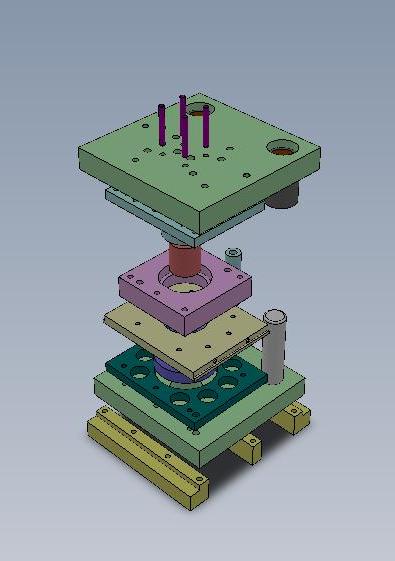

Progressive Dies / Tooling

Here at DACO Precision-Tool it’s our goal to design and build our progressive dies to exceed 100 strokes per minute to support high volume production.

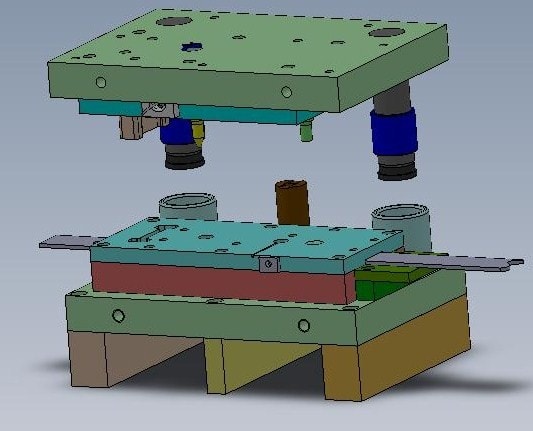

Compound Dies / Tooling

Here at DACO Precision-Tool it’s our goal to design and build our Compound Dies to exceed 100 strokes per minute to support high volume production. We can achieve this by building in sensors and other accessories to protect the die from damage. Cycle time is always kept in mind when designing and building our Compound

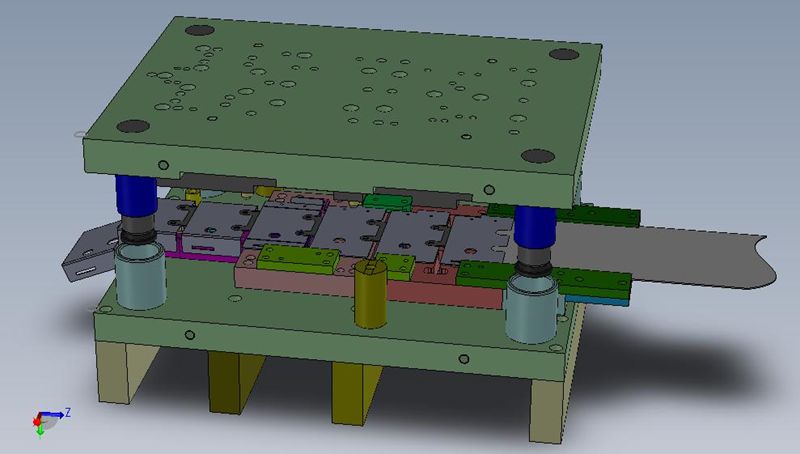

Pierce & Cut Dies / Tooling

Here at DACO Precision-Tool it’s our goal to design and build our Pierce & Cut Dies to exceed 100 strokes per minute to support high volume production. We can achieve this by building in sensors and other accessories to protect the die from damage. Cycle time is always kept in mind when designing and building our Pierce & Cut tooling. We can build the die to stamp the part at the accuracy you need.

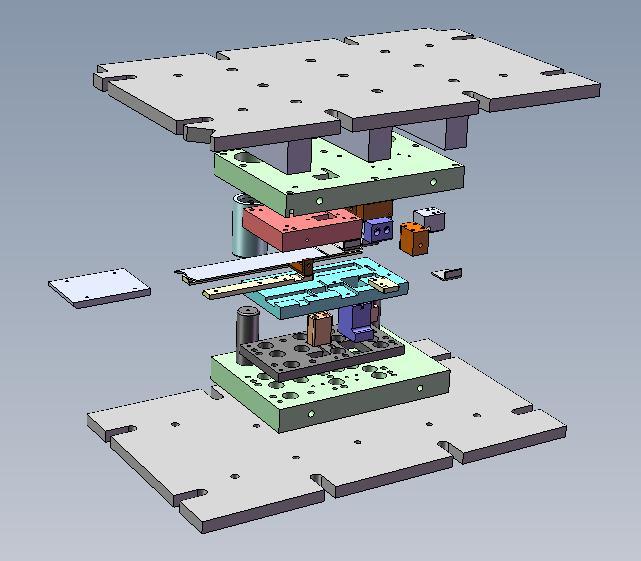

Bend & Form Dies / Tooling

Here at DACO Precision-Tool it’s our goal to design and build our Bend & Form Dies to make secondary forming as quick and easy as possible. We can achieve this by building in sensors and other accessories to protect the die from damage. Knowing that these parts will be run by an operator, we design the die to make inserting and removing the piece easy as possible to improve production rates.

Design, Build & Repair of Dies / Tooling

- Progressive dies for high-production, complex parts that may require multiple bends, drawing, or other processes.

- Compound dies for a high-accuracy, time and cost effective way to stamp flat simple parts such as washers.

- Pierce & Cut Dies for a very cost-effective way to quickly stamp flat, “rectangular” shaped parts such as shims, spacers, and plates. This die type reduces scrap

Progressive Dies / Tooling

Progressive Die Stamping is the process to modifying the raw material through a series of punch press cycles and the re-positioning of the raw material. You may see one or multiple processes combined to produce a finished part such as; Punching, Bending, Coining and Drawing or Tapping of the raw material. These processes; when performed in multiple operations or cycles of the press will produce a finished part through the progressive die/tool, saving you’re the expense of set-up time, and reduces the overall labor and production costs. Here at DACO Precision-Tool it’s our goal to design and build our progressive dies to exceed 100 strokes per minute to support high volume production. We can achieve this by building in sensors and other accessories to protect the die from damage. Cycle time is always kept in mind when designing and building our progressive die tooling. Parts are produced when the feed system pushes (strip or bulk coils) of raw material into the feed port of the progressive die tool; at each stroke or cycle of the press until the finished part is produced out the other end of the tooling. The feed rate of the material is controlled by the hard stops in each die section and the sensors built into the tooling. The final die section regardless of the number of tool/die sections required to produce a finished part; performs the cut-off operation. This separates the finished part from the carrying web; allowing the finished part to falls into the parts collection bin. The carrying web and material removed during the prior stages are conveyed to the scrap shoot and dropped into the scrap collection system. Use the “Request Information” selection to contact us and provide your design documentation with your contact information for our Engineering Department to review and provide you with a quote. Or if you have tooling that isn’t running right, or as quickly as you need or desire; let DACO Precision-Tool troubleshoot, modify, and repair existing tooling to get it up and running to a higher production rate for you.

-

Specifications

- Part Quantities

-

High Volume Tooling

Low Volume Tooling

Medium Volume Tooling

- Lead Times

-

We pride ourselves on quick turn around of design concept tooling to completed production tooling.

Your product’s design specifications, overall size and thickness of the material it will be forming will determine our tooling fabrication lead times.

- Tolerances

-

+/- .005 on average production tooling, but not limited to, DACO will meet or exceed customer requirements.

- Types of Tooling

-

Coining

Compound

Forming

Pierce & Cut

Progressive

Secondary

Trimming

- Tool Sizes

-

Tools weighing up to 20,000 lbs, up to 6’ long and 6’ wide

- Materials Used

-

1018

4140

A2

And Others

H13

M2

M4

S7

-

Capabilities

- Secondary Operations

-

And Others

Bending

Carbon and Graphite Electrodes

CNC Bar Work

CNC Machining

Coining

Cutting

EDM Services wire and conventional

Forming

Inserting

Laser Cutting

Piercing

Punching

Tapping

- Industries Served

-

Aerospace

Agriculture

And Many More

Automotive

Construction

Electronics

Food and Service

Government

Industrial

Machinery

Marine

Railroad and Mass Transit

Recreational Vehicle

- Quality Certification

-

ISO 9001/2008 CERTIFIED

- Engineering/Design Software

-

Auto Cad

Bridgeport

PowerMILL

PowerSHAPE

Pro/Engineer

SDRC

Solid Works

-

Equipment List:

- Stamping Production Equipment List

-

220-ton AIDA Dual Crank Punch Press, with ¼” x 18” Wide servo feed and stock straightener

180-ton Stamtec Press/Auto Feed, ¼ inch Capacity Rowe Servo-Feed With Power Straightener, Data Inst. (Wintress) Die Protection System

172-ton Iada 2 point gap frame press, with 2003 Link press controls, with 79.5” X 30” bolster (L/R-F/B) bed and full die cushion

160-ton Toledo #57 Straight Side with Die Cushion Punch Press (Secondary Production)

150-ton USI Clearing, O.B.I. Punch Press/ Auto Feed, 3/16 x 18 inches Capacity Perfecto Servo-Feed, Perfecto Power Straightener And Uncoiler, Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control, W/8-Sensor Die Protection System

150-ton Bliss O.B.I., Punch Press/Perfecto Servo Feed, Straightener, 3/16 x 18 inch Capacity

100-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

121-ton Komatsu OBS CNC 110svs Super Series Punch Press, CWP Servo-Feed, CWP Straightener/Reel, Modulating Drive To 75 feet Per Minute with Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

100-ton USI Clearing, Ac, O.B.I. Punch Press (Secondary Production)

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, Brueder 24 180-500.2 Combination Double End Reel and Straightener, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, P/A 5500 lbs Uncoiler, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

60-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Wintress Tonnage Monitor

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Clarktron Tonnage Monitor

56-ton #6 Minster A/C O.B.I. Punch Press (Secondary Production)

45-ton Toledo #5a A/C O.B.I. Punch Press (Secondary Production)

43-ton Johnson A/C O.B.I. Punch Press (Secondary Production)

35-ton Diamond A/C O.B.I. Punch Press with 6 x 6 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Diamond A/C O.B.I. Punch Press with 11/2 x 4 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Clearing Torc-Pac A/C, V/S & Stroke Punch Press

35-ton Rousselle O.B.I. Punch Press

30-ton Niagara #4.5 O.B.I. Punch Press

25-ton Wayne A/C with 6 x 6 inches Rapidair Auto Feed Punch Press, Clarktron Tonnage Monitor

20-ton L&J O.B.I. Punch Press

1 – Coilmatic Airfeed

Rowe 11 Ga. x 10 inches Straightener/Feeder

90-ton Amada/Pro-E CAM CNC Press Brake

50-ton Dries & Krump Press Brake

35 Ton Dries & Krump Press Brake

- Stamping/Tooling Machining Equipment List

-

1-Mitsubishi Boring Bar

Model M-HT11/1416

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 78.7 inches

Y-travel 59.1 inches

Z-travel 51.2 inches

Spindle 4.3 inches

Diameter with Stroke 19.7 inches

Horsepower 30

Loading Capacity of table 15,400 lbs.

Renishaw Probe Systems1-Femco Horizontal Boring Mill

Model WBMC-100R2

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 79 inches

Y-travel 71 inches

Z-travel 67 inches

Spindle 4 inches

Diameter with Stroke 28 inches

Milling Spindle Diameter 8.86 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 62 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 52 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model M-V5B

X-travel 31.5 inches

Y-travel 20.1 inches1-Mitsubishi CNC Vertical Machining Center

Model V-60E including all standard accessories and additional options1- Chevalier Fully Automatic Surface Grinder

Model: FSG-2060TC

Table Size: 21 x 62 inches

Maximum Grinding Length 60 inches

Maximum Grinding Width 20 inches

Maximum Distance from table to surface to Spindle Center Line 29.0 inches1-Chevalier Fully Automatic Precision Hydraulic Surface

Grinder Model: FSG-1632AD

Table Size: 15.75 x 31.5 inches

Maximum Grinding Length 32 inches

Maximum Grinding Width 16 inches

Maximum Distance from table to surface to Spindle Center Line 24.375 inches1-Chevalier Surface Grinder

Model: 618 High Precision2-Chevalier Surface Grinders

Model: 618M

Maximum Grinding Length 18 inches

Maximum Grinding Width 6 inches

Maximum Distance from table to surface to Spindle Center Line 18 inches

with Sony Digital Readouts1-Clausing/Metose Precision Lathe

Model: 1440 Bed 14 x 40 inches2-Bridgeport Series I Standard Mills

With Digital Readouts and Power Feed

Table travel x-axis 30 inches

Saddle travel y-axis 12 inches

Quill travel 5 inches

Knee travel z-axis 16 inches

Table size: 42 x 9 inches2-Clausing Vertical Milling Machines with Proto Trak MX2

- Secondary Operation Equipment

-

3/4 H.P. Delta Drill Press

Clausing 10 x 15 inches Automatic Wet Grinder, 1 x 12 inches Wheel

Harrig 6 x 12 inches Surface Grinder with 12 inches Electro Magnet

Wells 6 x 10 inches Cutoff Saw

Myford MG12 Grinder

2 – Boyer 6/12 Surface Grinder

Snow 3/8 inch Auto Tapping Machine

Brother BT-2-225 Auto Tapping Machine

Electra 6715 Auto Heat Treat And Draw Furnace

Wilson Model #4TT BB Hardness Tester

Wilson Model #HR 150A Hardness Tester

Yoder 10,000# 10 Ga. x 36 inches Wide Coil Slitting Line with Wean Over Arm/Coil Separator

10 Cubic Foot C&S Rapid Finish Deburring Machine with Auto Unload

10 Cubic Foot Rosler Automatic Heated Parts Drying Machine

10 Cubic Foot Sweco Rotary Deburring Machine

5 Cubic Foot Sweco Rotary Deburring Machine

Chicago Turret Self Feed Rivet Machine

Miller Portable Spot Welder

Miller Model #CP-200 Wire Feed Welder

A.O. Smith 350 Amp Welder

Craftsman #30-230 Portable Welder

Snapon Model #YA 3330 Portable Plasma Cutter

- Support Equipment

-

Japax LUX-3 Wire EDM, with 5.0 Bridgeport Easy Cam Software

Japax LXE Wire EDM, with 5.0 Bridgeport Easy Cam Software

Supermax 3 H.P. CNC 3-Axis Vertical Mill, Computer Programable, with Fixturing OR 6 inches Vise

ProtoTRAK K3S2 CNC Milling Machine With SM2 Control

ProtoTRAK K3 CNC Milling Machine With Edge Control

ProtoTRAK TRL 1440S CNC Lathe With SL Auto Control

Bridgeport 2 H.P. Milling Machine with Q.M.S Readout, 6 inches Vise

Excello 2 H.P. Ram Turret Milling Machine with TRAK 3 Position Readout, 6 inches Vise

Bridgeport 1 ½ inch H.P. Milling Machine with 6 inches Vise

Tech-Turn 13 inches Swing x 42 inches Lathe

Sullair 30 Hp Rotary Screw Air Compressor

Zeks Auto Air Drying System

25 H.P. Quincy Air Compressor with Aftercooler/Water Separator

15 H.P. Quincy Air Compressor with Aftercooler/Water Separator

5 H.P. Ingersol Rand Air Compressor

80 x 12 feet Die Racking System

Safety Kleen Parts Washer

Misc. Airfeeds, Uncoilers, And Straighteners

Misc. Master Dies, Inspection Equipment, Hand Tools, Tool Cutters, Tool Boxes, Etc.

Compound Dies / Tooling

Compound Die Stamping is the process where the die separates or blanks the part from a steel strip in one stroke. A Compound Die will perform multiple cuts or punches in one stroke, as compared to multiple strokes. This is a very cost effective method for stamping medium to high volume parts while keeping labor and die costs down. Compound Dies are often used to stamp simpler flat parts such as washers. Here at DACO Precision-Tool it’s our goal to design and build our Compound Dies to exceed 100 strokes per minute to support high volume production. We can achieve this by building in sensors and other accessories to protect the die from damage. Cycle time is always kept in mind when designing and building our Compound Die tooling. We can build the die to stamp the part at the accuracy you need. Parts are produced when the feed system pushes (strip or coil stock) of raw material into the Compound Die; at each stroke or cycle a finished flat part will blanked or released from the raw material. The feed rate of the material is determined by the size of the part. Larger parts need more time to exit the die, where smaller parts exit quicker allowing for faster run times. Typically, compound dies do not require a cut-off station because the parts are blanked through from the strip, but many times is added to help manage scrap material. Finished parts will be removed from the die by a knock-out and will fall onto a chute or slider where they flow into the collection bin. The scrap will exit the die in strip form or in piece form depending on if you’ve included a scrap cut-off station. Scrap can be collected in bins or hoppers on the exit end of the die. Use the “Request Information” selection to contact us and provide your design documentation with your contact information for our Engineering Department to review and provide you with a quote. Or if you have tooling that isn’t running right, or as quickly as you need or desire; let DACO Precision-Tool troubleshoot, modify, and repair existing tooling to get it up and running to a higher production rate for you.

-

Specifications

- Part Quantities

-

High Volume Tooling

Low Volume Tooling

Medium Volume Tooling

- Lead Times

-

We pride ourselves on quick turn around of design concept tooling to completed production tooling.

Your product’s design specifications, overall size and thickness of the material it will be forming will determine our tooling fabrication lead times.

- Tolerances

-

+/- .005 on average production tooling, but not limited to, DACO will meet or exceed customer requirements.

- Types of Tooling

-

Coining

Compound

Forming

Pierce & Cut

Progressive

Secondary

Trimming

- Tool Sizes

-

Tools weighing up to 20,000 lbs, up to 6’ long and 6’ wide

- Materials Used

-

1018

4140

A2

And Others

H13

M2

M4

S7

-

Capabilities

- Secondary Operations

-

And Others

Bending

Carbon and Graphite Electrodes

CNC Bar Work

CNC Machining

Coining

Cutting

EDM Services wire and conventional

Forming

Inserting

Laser Cutting

Piercing

Punching

Tapping

- Industries Served

-

Aerospace

Agriculture

And Many More

Automotive

Construction

Electronics

Food and Service

Government

Industrial

Machinery

Marine

Railroad and Mass Transit

Recreational Vehicle

- Quality Certification

-

ISO 9001/2008 CERTIFIED

- Engineering/Design Software

-

Auto Cad

Bridgeport

PowerMILL

PowerSHAPE

Pro/Engineer

SDRC

Solid Works

-

Equipment List:

- Stamping Production Equipment List

-

220-ton AIDA Dual Crank Punch Press, with ¼” x 18” Wide servo feed and stock straightener

180-ton Stamtec Press/Auto Feed, ¼ inch Capacity Rowe Servo-Feed With Power Straightener, Data Inst. (Wintress) Die Protection System

172-ton Iada 2 point gap frame press, with 2003 Link press controls, with 79.5” X 30” bolster (L/R-F/B) bed and full die cushion

160-ton Toledo #57 Straight Side with Die Cushion Punch Press (Secondary Production)

150-ton USI Clearing, O.B.I. Punch Press/ Auto Feed, 3/16 x 18 inches Capacity Perfecto Servo-Feed, Perfecto Power Straightener And Uncoiler, Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control, W/8-Sensor Die Protection System

150-ton Bliss O.B.I., Punch Press/Perfecto Servo Feed, Straightener, 3/16 x 18 inch Capacity

100-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

121-ton Komatsu OBS CNC 110svs Super Series Punch Press, CWP Servo-Feed, CWP Straightener/Reel, Modulating Drive To 75 feet Per Minute with Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

100-ton USI Clearing, Ac, O.B.I. Punch Press (Secondary Production)

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, Brueder 24 180-500.2 Combination Double End Reel and Straightener, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, P/A 5500 lbs Uncoiler, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

60-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Wintress Tonnage Monitor

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Clarktron Tonnage Monitor

56-ton #6 Minster A/C O.B.I. Punch Press (Secondary Production)

45-ton Toledo #5a A/C O.B.I. Punch Press (Secondary Production)

43-ton Johnson A/C O.B.I. Punch Press (Secondary Production)

35-ton Diamond A/C O.B.I. Punch Press with 6 x 6 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Diamond A/C O.B.I. Punch Press with 11/2 x 4 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Clearing Torc-Pac A/C, V/S & Stroke Punch Press

35-ton Rousselle O.B.I. Punch Press

30-ton Niagara #4.5 O.B.I. Punch Press

25-ton Wayne A/C with 6 x 6 inches Rapidair Auto Feed Punch Press, Clarktron Tonnage Monitor

20-ton L&J O.B.I. Punch Press

1 – Coilmatic Airfeed

Rowe 11 Ga. x 10 inches Straightener/Feeder

90-ton Amada/Pro-E CAM CNC Press Brake

50-ton Dries & Krump Press Brake

35 Ton Dries & Krump Press Brake

- Stamping/Tooling Machining Equipment List

-

1-Mitsubishi Boring Bar

Model M-HT11/1416

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 78.7 inches

Y-travel 59.1 inches

Z-travel 51.2 inches

Spindle 4.3 inches

Diameter with Stroke 19.7 inches

Horsepower 30

Loading Capacity of table 15,400 lbs.

Renishaw Probe Systems1-Femco Horizontal Boring Mill

Model WBMC-100R2

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 79 inches

Y-travel 71 inches

Z-travel 67 inches

Spindle 4 inches

Diameter with Stroke 28 inches

Milling Spindle Diameter 8.86 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 62 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 52 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model M-V5B

X-travel 31.5 inches

Y-travel 20.1 inches1-Mitsubishi CNC Vertical Machining Center

Model V-60E including all standard accessories and additional options1- Chevalier Fully Automatic Surface Grinder

Model: FSG-2060TC

Table Size: 21 x 62 inches

Maximum Grinding Length 60 inches

Maximum Grinding Width 20 inches

Maximum Distance from table to surface to Spindle Center Line 29.0 inches1-Chevalier Fully Automatic Precision Hydraulic Surface

Grinder Model: FSG-1632AD

Table Size: 15.75 x 31.5 inches

Maximum Grinding Length 32 inches

Maximum Grinding Width 16 inches

Maximum Distance from table to surface to Spindle Center Line 24.375 inches1-Chevalier Surface Grinder

Model: 618 High Precision2-Chevalier Surface Grinders

Model: 618M

Maximum Grinding Length 18 inches

Maximum Grinding Width 6 inches

Maximum Distance from table to surface to Spindle Center Line 18 inches

with Sony Digital Readouts1-Clausing/Metose Precision Lathe

Model: 1440 Bed 14 x 40 inches2-Bridgeport Series I Standard Mills

With Digital Readouts and Power Feed

Table travel x-axis 30 inches

Saddle travel y-axis 12 inches

Quill travel 5 inches

Knee travel z-axis 16 inches

Table size: 42 x 9 inches2-Clausing Vertical Milling Machines with Proto Trak MX2

- Secondary Operation Equipment

-

3/4 H.P. Delta Drill Press

Clausing 10 x 15 inches Automatic Wet Grinder, 1 x 12 inches Wheel

Harrig 6 x 12 inches Surface Grinder with 12 inches Electro Magnet

Wells 6 x 10 inches Cutoff Saw

Myford MG12 Grinder

2 – Boyer 6/12 Surface Grinder

Snow 3/8 inch Auto Tapping Machine

Brother BT-2-225 Auto Tapping Machine

Electra 6715 Auto Heat Treat And Draw Furnace

Wilson Model #4TT BB Hardness Tester

Wilson Model #HR 150A Hardness Tester

Yoder 10,000# 10 Ga. x 36 inches Wide Coil Slitting Line with Wean Over Arm/Coil Separator

10 Cubic Foot C&S Rapid Finish Deburring Machine with Auto Unload

10 Cubic Foot Rosler Automatic Heated Parts Drying Machine

10 Cubic Foot Sweco Rotary Deburring Machine

5 Cubic Foot Sweco Rotary Deburring Machine

Chicago Turret Self Feed Rivet Machine

Miller Portable Spot Welder

Miller Model #CP-200 Wire Feed Welder

A.O. Smith 350 Amp Welder

Craftsman #30-230 Portable Welder

Snapon Model #YA 3330 Portable Plasma Cutter

- Support Equipment

-

Japax LUX-3 Wire EDM, with 5.0 Bridgeport Easy Cam Software

Japax LXE Wire EDM, with 5.0 Bridgeport Easy Cam Software

Supermax 3 H.P. CNC 3-Axis Vertical Mill, Computer Programable, with Fixturing OR 6 inches Vise

ProtoTRAK K3S2 CNC Milling Machine With SM2 Control

ProtoTRAK K3 CNC Milling Machine With Edge Control

ProtoTRAK TRL 1440S CNC Lathe With SL Auto Control

Bridgeport 2 H.P. Milling Machine with Q.M.S Readout, 6 inches Vise

Excello 2 H.P. Ram Turret Milling Machine with TRAK 3 Position Readout, 6 inches Vise

Bridgeport 1 ½ inch H.P. Milling Machine with 6 inches Vise

Tech-Turn 13 inches Swing x 42 inches Lathe

Sullair 30 Hp Rotary Screw Air Compressor

Zeks Auto Air Drying System

25 H.P. Quincy Air Compressor with Aftercooler/Water Separator

15 H.P. Quincy Air Compressor with Aftercooler/Water Separator

5 H.P. Ingersol Rand Air Compressor

80 x 12 feet Die Racking System

Safety Kleen Parts Washer

Misc. Airfeeds, Uncoilers, And Straighteners

Misc. Master Dies, Inspection Equipment, Hand Tools, Tool Cutters, Tool Boxes, Etc.

Pierce & Cut Dies / Tooling

Pierce & Cut Die Stamping is a very cost-effective way to quickly stamp flat, “rectangular” shaped parts such as shims, spacers, and plates. A benefit of Pierce & Cut Die Stamping is that raw material is better utilized reducing the total amount of scrap material produced over other stamping methods. Here at DACO Precision-Tool it’s our goal to design and build our Pierce & Cut Dies to exceed 100 strokes per minute to support high volume production. We can achieve this by building in sensors and other accessories to protect the die from damage. Cycle time is always kept in mind when designing and building our Pierce & Cut tooling. We can build the die to stamp the part at the accuracy you need. Parts are produced when the feed system pushes (strip or coil stock) of raw material into the Pierce & Cut Die; at each stroke or cycle a finished flat part will be cut off the end of the strip. This type of die requires that the raw material width is cut to the size needed for the part. The feed rate of the material is determined by the length of the part. Longer parts need more time per stroke to get the strip in position for the next stroke. Thickness also influences that feed rate. Thicker parts need the press to run a bit slower than thinner parts. Pierce & Cut Dies punch out holes and notches on the first stroke, and then the second and final stroke is the cut-off, where the completed part is cut from the strip. Once cut from the strip finished parts will be exit the die and will fall onto a chute or slider where they flow into the collection bin. The scrap is typically punched through the die and is collected under the press, or next to the press using chutes or slides. Use the “Request Information” selection to contact us and provide your design documentation with your contact information for our Engineering Department to review and provide you with a quote. Or if you have tooling that isn’t running right, or as quickly as you need or desire; let DACO Precision-Tool troubleshoot, modify, and repair existing tooling to get it up and running to a higher production rate for you.

-

Specifications

- Part Quantities

-

High Volume Tooling

Low Volume Tooling

Medium Volume Tooling

- Lead Times

-

We pride ourselves on quick turn around of design concept tooling to completed production tooling.

Your product’s design specifications, overall size and thickness of the material it will be forming will determine our tooling fabrication lead times.

- Tolerances

-

+/- .005 on average production tooling, but not limited to, DACO will meet or exceed customer requirements.

- Types of Tooling

-

Coining

Compound

Forming

Pierce & Cut

Progressive

Secondary

Trimming

- Tool Sizes

-

Tools weighing up to 20,000 lbs, up to 6’ long and 6’ wide

- Materials Used

-

1018

4140

A2

And Others

H13

M2

M4

S7

-

Capabilities

- Secondary Operations

-

And Others

Bending

Carbon and Graphite Electrodes

CNC Bar Work

CNC Machining

Coining

Cutting

EDM Services wire and conventional

Forming

Inserting

Laser Cutting

Piercing

Punching

Tapping

- Industries Served

-

Aerospace

Agriculture

And Many More

Automotive

Construction

Electronics

Food and Service

Government

Industrial

Machinery

Marine

Railroad and Mass Transit

Recreational Vehicle

- Quality Certification

-

ISO 9001/2008 CERTIFIED

- Engineering/Design Software

-

Auto Cad

Bridgeport

PowerMILL

PowerSHAPE

Pro/Engineer

SDRC

Solid Works

-

Equipment List:

- Stamping Production Equipment List

-

220-ton AIDA Dual Crank Punch Press, with ¼” x 18” Wide servo feed and stock straightener

180-ton Stamtec Press/Auto Feed, ¼ inch Capacity Rowe Servo-Feed With Power Straightener, Data Inst. (Wintress) Die Protection System

172-ton Iada 2 point gap frame press, with 2003 Link press controls, with 79.5” X 30” bolster (L/R-F/B) bed and full die cushion

160-ton Toledo #57 Straight Side with Die Cushion Punch Press (Secondary Production)

150-ton USI Clearing, O.B.I. Punch Press/ Auto Feed, 3/16 x 18 inches Capacity Perfecto Servo-Feed, Perfecto Power Straightener And Uncoiler, Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control, W/8-Sensor Die Protection System

150-ton Bliss O.B.I., Punch Press/Perfecto Servo Feed, Straightener, 3/16 x 18 inch Capacity

100-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

121-ton Komatsu OBS CNC 110svs Super Series Punch Press, CWP Servo-Feed, CWP Straightener/Reel, Modulating Drive To 75 feet Per Minute with Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

100-ton USI Clearing, Ac, O.B.I. Punch Press (Secondary Production)

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, Brueder 24 180-500.2 Combination Double End Reel and Straightener, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, P/A 5500 lbs Uncoiler, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

60-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Wintress Tonnage Monitor

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Clarktron Tonnage Monitor

56-ton #6 Minster A/C O.B.I. Punch Press (Secondary Production)

45-ton Toledo #5a A/C O.B.I. Punch Press (Secondary Production)

43-ton Johnson A/C O.B.I. Punch Press (Secondary Production)

35-ton Diamond A/C O.B.I. Punch Press with 6 x 6 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Diamond A/C O.B.I. Punch Press with 11/2 x 4 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Clearing Torc-Pac A/C, V/S & Stroke Punch Press

35-ton Rousselle O.B.I. Punch Press

30-ton Niagara #4.5 O.B.I. Punch Press

25-ton Wayne A/C with 6 x 6 inches Rapidair Auto Feed Punch Press, Clarktron Tonnage Monitor

20-ton L&J O.B.I. Punch Press

1 – Coilmatic Airfeed

Rowe 11 Ga. x 10 inches Straightener/Feeder

90-ton Amada/Pro-E CAM CNC Press Brake

50-ton Dries & Krump Press Brake

35 Ton Dries & Krump Press Brake

- Stamping/Tooling Machining Equipment List

-

1-Mitsubishi Boring Bar

Model M-HT11/1416

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 78.7 inches

Y-travel 59.1 inches

Z-travel 51.2 inches

Spindle 4.3 inches

Diameter with Stroke 19.7 inches

Horsepower 30

Loading Capacity of table 15,400 lbs.

Renishaw Probe Systems1-Femco Horizontal Boring Mill

Model WBMC-100R2

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 79 inches

Y-travel 71 inches

Z-travel 67 inches

Spindle 4 inches

Diameter with Stroke 28 inches

Milling Spindle Diameter 8.86 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 62 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 52 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model M-V5B

X-travel 31.5 inches

Y-travel 20.1 inches1-Mitsubishi CNC Vertical Machining Center

Model V-60E including all standard accessories and additional options1- Chevalier Fully Automatic Surface Grinder

Model: FSG-2060TC

Table Size: 21 x 62 inches

Maximum Grinding Length 60 inches

Maximum Grinding Width 20 inches

Maximum Distance from table to surface to Spindle Center Line 29.0 inches1-Chevalier Fully Automatic Precision Hydraulic Surface

Grinder Model: FSG-1632AD

Table Size: 15.75 x 31.5 inches

Maximum Grinding Length 32 inches

Maximum Grinding Width 16 inches

Maximum Distance from table to surface to Spindle Center Line 24.375 inches1-Chevalier Surface Grinder

Model: 618 High Precision2-Chevalier Surface Grinders

Model: 618M

Maximum Grinding Length 18 inches

Maximum Grinding Width 6 inches

Maximum Distance from table to surface to Spindle Center Line 18 inches

with Sony Digital Readouts1-Clausing/Metose Precision Lathe

Model: 1440 Bed 14 x 40 inches2-Bridgeport Series I Standard Mills

With Digital Readouts and Power Feed

Table travel x-axis 30 inches

Saddle travel y-axis 12 inches

Quill travel 5 inches

Knee travel z-axis 16 inches

Table size: 42 x 9 inches2-Clausing Vertical Milling Machines with Proto Trak MX2

- Secondary Operation Equipment

-

3/4 H.P. Delta Drill Press

Clausing 10 x 15 inches Automatic Wet Grinder, 1 x 12 inches Wheel

Harrig 6 x 12 inches Surface Grinder with 12 inches Electro Magnet

Wells 6 x 10 inches Cutoff Saw

Myford MG12 Grinder

2 – Boyer 6/12 Surface Grinder

Snow 3/8 inch Auto Tapping Machine

Brother BT-2-225 Auto Tapping Machine

Electra 6715 Auto Heat Treat And Draw Furnace

Wilson Model #4TT BB Hardness Tester

Wilson Model #HR 150A Hardness Tester

Yoder 10,000# 10 Ga. x 36 inches Wide Coil Slitting Line with Wean Over Arm/Coil Separator

10 Cubic Foot C&S Rapid Finish Deburring Machine with Auto Unload

10 Cubic Foot Rosler Automatic Heated Parts Drying Machine

10 Cubic Foot Sweco Rotary Deburring Machine

5 Cubic Foot Sweco Rotary Deburring Machine

Chicago Turret Self Feed Rivet Machine

Miller Portable Spot Welder

Miller Model #CP-200 Wire Feed Welder

A.O. Smith 350 Amp Welder

Craftsman #30-230 Portable Welder

Snapon Model #YA 3330 Portable Plasma Cutter

- Support Equipment

-

Japax LUX-3 Wire EDM, with 5.0 Bridgeport Easy Cam Software

Japax LXE Wire EDM, with 5.0 Bridgeport Easy Cam Software

Supermax 3 H.P. CNC 3-Axis Vertical Mill, Computer Programable, with Fixturing OR 6 inches Vise

ProtoTRAK K3S2 CNC Milling Machine With SM2 Control

ProtoTRAK K3 CNC Milling Machine With Edge Control

ProtoTRAK TRL 1440S CNC Lathe With SL Auto Control

Bridgeport 2 H.P. Milling Machine with Q.M.S Readout, 6 inches Vise

Excello 2 H.P. Ram Turret Milling Machine with TRAK 3 Position Readout, 6 inches Vise

Bridgeport 1 ½ inch H.P. Milling Machine with 6 inches Vise

Tech-Turn 13 inches Swing x 42 inches Lathe

Sullair 30 Hp Rotary Screw Air Compressor

Zeks Auto Air Drying System

25 H.P. Quincy Air Compressor with Aftercooler/Water Separator

15 H.P. Quincy Air Compressor with Aftercooler/Water Separator

5 H.P. Ingersol Rand Air Compressor

80 x 12 feet Die Racking System

Safety Kleen Parts Washer

Misc. Airfeeds, Uncoilers, And Straighteners

Misc. Master Dies, Inspection Equipment, Hand Tools, Tool Cutters, Tool Boxes, Etc.

Bend & Form Dies / Tooling

DACO can design and build “bending and forming” tools, usually considered a secondary operation where a flat blank or part is placed into the tool and formed and bent with one or more operation or single press cycle, Usually lower volume parts will be formed and produced from secondary bending and forming tools. Bend/Form Dies are used to bend, form, or draw the material or part into a variety of angles and shapes. This can be done as a secondary tool and operation, or it can be built into a progressive die. DACO Precision-Tool uses a variety of 2D and 3D cad/cam Software to develop, design, and plan the layout of our dies. (see below for the full software list & details). We have the resources to build a die for any application. When high volumes of production are expected, we can build a dependable tool with longevity in mind. We can also produce low-cost tools for prototyping and sampling applications. Die protection is always on our mind, and DACO Precision-Tool can build in sensors that will help prevent costly damage to the die. Do you have a tool/die that isn’t running right, or as quickly as you need? DACO Precision-Tool can troubleshoot, modify, and repair existing tooling to get it up and running like you need it to. Use the “Request Information” selection to contact us. Attach your design documentation along with your contact information for our Engineering Department to review and provide you with a quote.

-

Specifications

- Part Quantities

-

High Volume Tooling

Low Volume Tooling

Medium Volume Tooling

- Lead Times

-

We pride ourselves on quick turn around of design concept tooling to completed production tooling.

Your product’s design specifications, overall size and thickness of the material it will be forming will determine our tooling fabrication lead times.

- Tolerances

-

+/- .005 on average production tooling, but not limited to, DACO will meet or exceed customer requirements.

- Tool Sizes

-

Tools weighing up to 20,000 lbs, up to 6’ long and 6’ wide

- Materials Used

-

1018

4140

A2

And Others

H13

M2

M4

S7

-

Capabilities

- Secondary Operations

-

And Others

Bending

Carbon and Graphite Electrodes

CNC Bar Work

CNC Machining

Coining

Cutting

EDM Services wire and conventional

Forming

Inserting

Laser Cutting

Piercing

Punching

Tapping

- Industries Served

-

Aerospace

Agriculture

And Many More

Automotive

Construction

Electronics

Food and Service

Government

Industrial

Machinery

Marine

Railroad and Mass Transit

Recreational Vehicle

- Quality Certification

-

ISO 9001/2008 CERTIFIED

- Engineering/Design Software

-

Auto Cad

Bridgeport

PowerMILL

PowerSHAPE

Pro/Engineer

SDRC

Solid Works

-

Equipment List:

- Stamping Production Equipment List

-

220-ton AIDA Dual Crank Punch Press, with ¼” x 18” Wide servo feed and stock straightener

180-ton Stamtec Press/Auto Feed, ¼ inch Capacity Rowe Servo-Feed With Power Straightener, Data Inst. (Wintress) Die Protection System

172-ton Iada 2 point gap frame press, with 2003 Link press controls, with 79.5” X 30” bolster (L/R-F/B) bed and full die cushion

160-ton Toledo #57 Straight Side with Die Cushion Punch Press (Secondary Production)

150-ton USI Clearing, O.B.I. Punch Press/ Auto Feed, 3/16 x 18 inches Capacity Perfecto Servo-Feed, Perfecto Power Straightener And Uncoiler, Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control, W/8-Sensor Die Protection System

150-ton Bliss O.B.I., Punch Press/Perfecto Servo Feed, Straightener, 3/16 x 18 inch Capacity

100-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

121-ton Komatsu OBS CNC 110svs Super Series Punch Press, CWP Servo-Feed, CWP Straightener/Reel, Modulating Drive To 75 feet Per Minute with Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

100-ton USI Clearing, Ac, O.B.I. Punch Press (Secondary Production)

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, Brueder 24 180-500.2 Combination Double End Reel and Straightener, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, P/A 5500 lbs Uncoiler, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

60-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Wintress Tonnage Monitor

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Clarktron Tonnage Monitor

56-ton #6 Minster A/C O.B.I. Punch Press (Secondary Production)

45-ton Toledo #5a A/C O.B.I. Punch Press (Secondary Production)

43-ton Johnson A/C O.B.I. Punch Press (Secondary Production)

35-ton Diamond A/C O.B.I. Punch Press with 6 x 6 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Diamond A/C O.B.I. Punch Press with 11/2 x 4 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Clearing Torc-Pac A/C, V/S & Stroke Punch Press

35-ton Rousselle O.B.I. Punch Press

30-ton Niagara #4.5 O.B.I. Punch Press

25-ton Wayne A/C with 6 x 6 inches Rapidair Auto Feed Punch Press, Clarktron Tonnage Monitor

20-ton L&J O.B.I. Punch Press

1 – Coilmatic Airfeed

Rowe 11 Ga. x 10 inches Straightener/Feeder

90-ton Amada/Pro-E CAM CNC Press Brake

50-ton Dries & Krump Press Brake

35 Ton Dries & Krump Press Brake

- Stamping/Tooling Machining Equipment List

-

1-Mitsubishi Boring Bar

Model M-HT11/1416

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 78.7 inches

Y-travel 59.1 inches

Z-travel 51.2 inches

Spindle 4.3 inches

Diameter with Stroke 19.7 inches

Horsepower 30

Loading Capacity of table 15,400 lbs.

Renishaw Probe Systems1-Femco Horizontal Boring Mill

Model WBMC-100R2

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 79 inches

Y-travel 71 inches

Z-travel 67 inches

Spindle 4 inches

Diameter with Stroke 28 inches

Milling Spindle Diameter 8.86 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 62 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 52 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model M-V5B

X-travel 31.5 inches

Y-travel 20.1 inches1-Mitsubishi CNC Vertical Machining Center

Model V-60E including all standard accessories and additional options1- Chevalier Fully Automatic Surface Grinder

Model: FSG-2060TC

Table Size: 21 x 62 inches

Maximum Grinding Length 60 inches

Maximum Grinding Width 20 inches

Maximum Distance from table to surface to Spindle Center Line 29.0 inches1-Chevalier Fully Automatic Precision Hydraulic Surface

Grinder Model: FSG-1632AD

Table Size: 15.75 x 31.5 inches

Maximum Grinding Length 32 inches

Maximum Grinding Width 16 inches

Maximum Distance from table to surface to Spindle Center Line 24.375 inches1-Chevalier Surface Grinder

Model: 618 High Precision2-Chevalier Surface Grinders

Model: 618M

Maximum Grinding Length 18 inches

Maximum Grinding Width 6 inches

Maximum Distance from table to surface to Spindle Center Line 18 inches

with Sony Digital Readouts1-Clausing/Metose Precision Lathe

Model: 1440 Bed 14 x 40 inches2-Bridgeport Series I Standard Mills

With Digital Readouts and Power Feed

Table travel x-axis 30 inches

Saddle travel y-axis 12 inches

Quill travel 5 inches

Knee travel z-axis 16 inches

Table size: 42 x 9 inches2-Clausing Vertical Milling Machines with Proto Trak MX2

- Secondary Operation Equipment

-

3/4 H.P. Delta Drill Press

Clausing 10 x 15 inches Automatic Wet Grinder, 1 x 12 inches Wheel

Harrig 6 x 12 inches Surface Grinder with 12 inches Electro Magnet

Wells 6 x 10 inches Cutoff Saw

Myford MG12 Grinder

2 – Boyer 6/12 Surface Grinder

Snow 3/8 inch Auto Tapping Machine

Brother BT-2-225 Auto Tapping Machine

Electra 6715 Auto Heat Treat And Draw Furnace

Wilson Model #4TT BB Hardness Tester

Wilson Model #HR 150A Hardness Tester

Yoder 10,000# 10 Ga. x 36 inches Wide Coil Slitting Line with Wean Over Arm/Coil Separator

10 Cubic Foot C&S Rapid Finish Deburring Machine with Auto Unload

10 Cubic Foot Rosler Automatic Heated Parts Drying Machine

10 Cubic Foot Sweco Rotary Deburring Machine

5 Cubic Foot Sweco Rotary Deburring Machine

Chicago Turret Self Feed Rivet Machine

Miller Portable Spot Welder

Miller Model #CP-200 Wire Feed Welder

A.O. Smith 350 Amp Welder

Craftsman #30-230 Portable Welder

Snapon Model #YA 3330 Portable Plasma Cutter

- Support Equipment

-

Japax LUX-3 Wire EDM, with 5.0 Bridgeport Easy Cam Software

Japax LXE Wire EDM, with 5.0 Bridgeport Easy Cam Software

Supermax 3 H.P. CNC 3-Axis Vertical Mill, Computer Programable, with Fixturing OR 6 inches Vise

ProtoTRAK K3S2 CNC Milling Machine With SM2 Control

ProtoTRAK K3 CNC Milling Machine With Edge Control

ProtoTRAK TRL 1440S CNC Lathe With SL Auto Control

Bridgeport 2 H.P. Milling Machine with Q.M.S Readout, 6 inches Vise

Excello 2 H.P. Ram Turret Milling Machine with TRAK 3 Position Readout, 6 inches Vise

Bridgeport 1 ½ inch H.P. Milling Machine with 6 inches Vise

Tech-Turn 13 inches Swing x 42 inches Lathe

Sullair 30 Hp Rotary Screw Air Compressor

Zeks Auto Air Drying System

25 H.P. Quincy Air Compressor with Aftercooler/Water Separator

15 H.P. Quincy Air Compressor with Aftercooler/Water Separator

5 H.P. Ingersol Rand Air Compressor

80 x 12 feet Die Racking System

Safety Kleen Parts Washer

Misc. Airfeeds, Uncoilers, And Straighteners

Misc. Master Dies, Inspection Equipment, Hand Tools, Tool Cutters, Tool Boxes, Etc.

Design, Build & Repair of Dies / Tooling

DACO Precision-Tool can make tools and dies for many metal and non-metal fabrication processes. Whether it is something as simple as punching out a washer, or part that is very complex; we can build a die that will get the job done. We can build a die that will fit your exact application. Common die types include:

- Progressive dies for high-production, complex parts that may require multiple bends, drawing, or other processes.

- Compound dies for a high-accuracy, time and cost effective way to stamp flat simple parts such as washers.

- Pierce & Cut Dies for a very cost-effective way to quickly stamp flat, “rectangular” shaped parts such as shims, spacers, and plates. This die type reduces scrap…and your raw material cost.

- Bend/Form Dies are used to form a part into a variety of angles and shapes. This can be done as a secondary tool and operation, or it can be built into a progressive die.

-

Specifications

- Part Quantities

-

High Volume Tooling

Low Volume Tooling

Medium Volume Tooling

- Lead Times

-

We pride ourselves on quick turn around of design concept tooling to completed production tooling.

Your product’s design specifications, overall size and thickness of the material it will be forming will determine our tooling fabrication lead times.

- Tolerances

-

+/- .005 on average production tooling, but not limited to, DACO will meet or exceed customer requirements.

- Types of Tooling

-

Coining

Compound

Forming

Pierce & Cut

Progressive

Secondary

Trimming

- Tool Sizes

-

Tools weighing up to 20,000 lbs, up to 6’ long and 6’ wide

- Materials Used

-

1018

4140

A2

And Others

H13

M2

M4

S7

-

Capabilities

- Secondary Operations

-

And Others

Bending

Carbon and Graphite Electrodes

CNC Bar Work

CNC Machining

Coining

Cutting

EDM Services wire and conventional

Forming

Inserting

Laser Cutting

Piercing

Punching

Tapping

- Industries Served

-

Aerospace

Agriculture

And Many More

Automotive

Construction

Electronics

Food and Service

Government

Industrial

Machinery

Marine

Railroad and Mass Transit

Recreational Vehicle

- Quality Certification

-

ISO 9001/2008 CERTIFIED

- Engineering/Design Software

-

Auto Cad

Bridgeport

PowerMILL

PowerSHAPE

Pro/Engineer

SDRC

Solid Works

-

Equipment List:

- Stamping Production Equipment List

-

220-ton AIDA Dual Crank Punch Press, with ¼” x 18” Wide servo feed and stock straightener

180-ton Stamtec Press/Auto Feed, ¼ inch Capacity Rowe Servo-Feed With Power Straightener, Data Inst. (Wintress) Die Protection System

172-ton Iada 2 point gap frame press, with 2003 Link press controls, with 79.5” X 30” bolster (L/R-F/B) bed and full die cushion

160-ton Toledo #57 Straight Side with Die Cushion Punch Press (Secondary Production)

150-ton USI Clearing, O.B.I. Punch Press/ Auto Feed, 3/16 x 18 inches Capacity Perfecto Servo-Feed, Perfecto Power Straightener And Uncoiler, Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control, W/8-Sensor Die Protection System

150-ton Bliss O.B.I., Punch Press/Perfecto Servo Feed, Straightener, 3/16 x 18 inch Capacity

100-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

121-ton Komatsu OBS CNC 110svs Super Series Punch Press, CWP Servo-Feed, CWP Straightener/Reel, Modulating Drive To 75 feet Per Minute with Ultrasonic Loop Control, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

100-ton USI Clearing, Ac, O.B.I. Punch Press (Secondary Production)

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, Brueder 24 180-500.2 Combination Double End Reel and Straightener, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

66-ton GI-60 Stamtec A/C, V/S OBS CNC Series Punch Press, Rowe 3/16 x 15 inches Dominator Servo Feed, P/A 5500 lbs Uncoiler, Data Inst. Smart Pac Automation Control with 8-Sensor Die Protection System

60-ton Bliss O.B.I., A/C Punch Press (Secondary Production)

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Wintress Tonnage Monitor

60-ton Johnson A/C, V/S O.B.I. Punch Press with 8 inches Rapidair Autofeed, Clarktron Tonnage Monitor

56-ton #6 Minster A/C O.B.I. Punch Press (Secondary Production)

45-ton Toledo #5a A/C O.B.I. Punch Press (Secondary Production)

43-ton Johnson A/C O.B.I. Punch Press (Secondary Production)

35-ton Diamond A/C O.B.I. Punch Press with 6 x 6 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Diamond A/C O.B.I. Punch Press with 11/2 x 4 inches Rapidair Autofeed, Wintress Tonnage Monitor

35-ton Clearing Torc-Pac A/C, V/S & Stroke Punch Press

35-ton Rousselle O.B.I. Punch Press

30-ton Niagara #4.5 O.B.I. Punch Press

25-ton Wayne A/C with 6 x 6 inches Rapidair Auto Feed Punch Press, Clarktron Tonnage Monitor

20-ton L&J O.B.I. Punch Press

1 – Coilmatic Airfeed

Rowe 11 Ga. x 10 inches Straightener/Feeder

90-ton Amada/Pro-E CAM CNC Press Brake

50-ton Dries & Krump Press Brake

35 Ton Dries & Krump Press Brake

- Stamping/Tooling Machining Equipment List

-

1-Mitsubishi Boring Bar

Model M-HT11/1416

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 78.7 inches

Y-travel 59.1 inches

Z-travel 51.2 inches

Spindle 4.3 inches

Diameter with Stroke 19.7 inches

Horsepower 30

Loading Capacity of table 15,400 lbs.

Renishaw Probe Systems1-Femco Horizontal Boring Mill

Model WBMC-100R2

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 79 inches

Y-travel 71 inches

Z-travel 67 inches

Spindle 4 inches

Diameter with Stroke 28 inches

Milling Spindle Diameter 8.86 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 62 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 52 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model M-V5B

X-travel 31.5 inches

Y-travel 20.1 inches1-Mitsubishi CNC Vertical Machining Center

Model V-60E including all standard accessories and additional options1- Chevalier Fully Automatic Surface Grinder

Model: FSG-2060TC

Table Size: 21 x 62 inches

Maximum Grinding Length 60 inches

Maximum Grinding Width 20 inches

Maximum Distance from table to surface to Spindle Center Line 29.0 inches1-Chevalier Fully Automatic Precision Hydraulic Surface

Grinder Model: FSG-1632AD

Table Size: 15.75 x 31.5 inches

Maximum Grinding Length 32 inches

Maximum Grinding Width 16 inches

Maximum Distance from table to surface to Spindle Center Line 24.375 inches1-Chevalier Surface Grinder

Model: 618 High Precision2-Chevalier Surface Grinders

Model: 618M

Maximum Grinding Length 18 inches

Maximum Grinding Width 6 inches

Maximum Distance from table to surface to Spindle Center Line 18 inches

with Sony Digital Readouts1-Clausing/Metose Precision Lathe

Model: 1440 Bed 14 x 40 inches2-Bridgeport Series I Standard Mills

With Digital Readouts and Power Feed

Table travel x-axis 30 inches

Saddle travel y-axis 12 inches

Quill travel 5 inches

Knee travel z-axis 16 inches

Table size: 42 x 9 inches2-Clausing Vertical Milling Machines with Proto Trak MX2

- Secondary Operation Equipment

-

3/4 H.P. Delta Drill Press

Clausing 10 x 15 inches Automatic Wet Grinder, 1 x 12 inches Wheel

Harrig 6 x 12 inches Surface Grinder with 12 inches Electro Magnet

Wells 6 x 10 inches Cutoff Saw

Myford MG12 Grinder

2 – Boyer 6/12 Surface Grinder

Snow 3/8 inch Auto Tapping Machine

Brother BT-2-225 Auto Tapping Machine

Electra 6715 Auto Heat Treat And Draw Furnace

Wilson Model #4TT BB Hardness Tester

Wilson Model #HR 150A Hardness Tester

Yoder 10,000# 10 Ga. x 36 inches Wide Coil Slitting Line with Wean Over Arm/Coil Separator

10 Cubic Foot C&S Rapid Finish Deburring Machine with Auto Unload

10 Cubic Foot Rosler Automatic Heated Parts Drying Machine

10 Cubic Foot Sweco Rotary Deburring Machine

5 Cubic Foot Sweco Rotary Deburring Machine

Chicago Turret Self Feed Rivet Machine

Miller Portable Spot Welder

Miller Model #CP-200 Wire Feed Welder

A.O. Smith 350 Amp Welder

Craftsman #30-230 Portable Welder

Snapon Model #YA 3330 Portable Plasma Cutter

- Support Equipment

-

Japax LUX-3 Wire EDM, with 5.0 Bridgeport Easy Cam Software

Japax LXE Wire EDM, with 5.0 Bridgeport Easy Cam Software

Supermax 3 H.P. CNC 3-Axis Vertical Mill, Computer Programable, with Fixturing OR 6 inches Vise

ProtoTRAK K3S2 CNC Milling Machine With SM2 Control

ProtoTRAK K3 CNC Milling Machine With Edge Control

ProtoTRAK TRL 1440S CNC Lathe With SL Auto Control

Bridgeport 2 H.P. Milling Machine with Q.M.S Readout, 6 inches Vise

Excello 2 H.P. Ram Turret Milling Machine with TRAK 3 Position Readout, 6 inches Vise

Bridgeport 1 ½ inch H.P. Milling Machine with 6 inches Vise

Tech-Turn 13 inches Swing x 42 inches Lathe

Sullair 30 Hp Rotary Screw Air Compressor

Zeks Auto Air Drying System

25 H.P. Quincy Air Compressor with Aftercooler/Water Separator

15 H.P. Quincy Air Compressor with Aftercooler/Water Separator

5 H.P. Ingersol Rand Air Compressor

80 x 12 feet Die Racking System

Safety Kleen Parts Washer

Misc. Airfeeds, Uncoilers, And Straighteners

Misc. Master Dies, Inspection Equipment, Hand Tools, Tool Cutters, Tool Boxes, Etc.