Die Cast Tooling

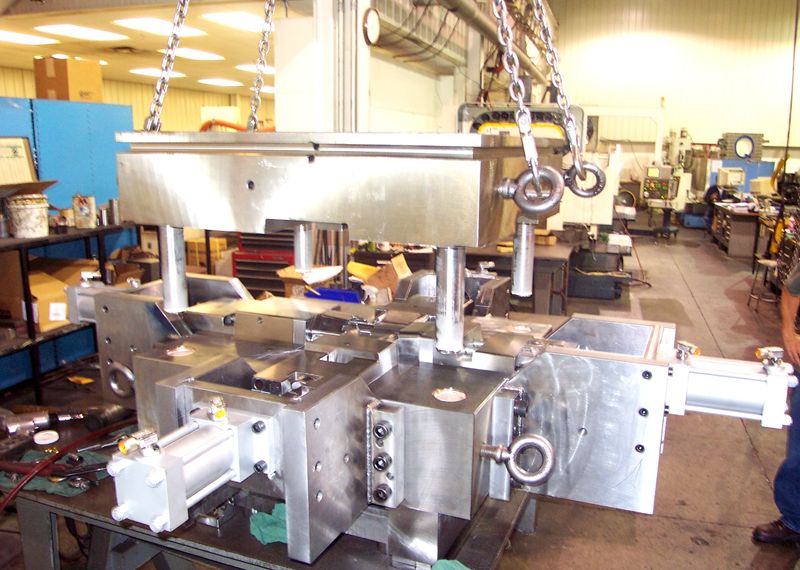

Die casting and injection tooling types that we manufacture include die cast molds, plastic injection molds, multi-cavity dies, and master unit dies (MUD).

We build die cast tooling with single or multiple cavities for brass, zinc and aluminum castings. If required, we can offer trim tools for cast parts as well.

Plastic injection molds are available

Design, Build & Repair of Tooling

DACO can help and assist you with all tooling design, and construction on new and existing tooling, and offer part cost savings or over all tool cost saving options depending on the actual tool design. DACO can also help with all types of tooling and needed tooling repairs, including punch & die, core & cavity, locate and replace almost any components, and can completely reconstruct old or broken down tooling if needed.

Plastic Injection Tooling

To build a long-lasting quality die, DACO insists on using high quality, certified materials when constructing any tooling. Our tooling technicians work very hard to provide customers with a high-performing, quality mold that will run thousands of high quality

Multi-Cavity Tooling

To build a long-lasting quality die, DACO insists on using high quality, certified materials when constructing any tooling. Our tooling technicians work very hard to provide customers with a high-performing, quality mold that will run thousands of high quality parts.

DACO has many years of experience in designing and building die cast & plastic injection molds. We are highly qualified and

Tooling Revisions & Updates

To make sure the repair/adjustment will perform and will be long-lasting, DACO insists on using high quality, certified materials when constructing any tooling. Our tooling technicians work very hard to provide customers with a high-performing, quality mold that will run thousands of high quality parts.

DACO has many years of experience in designing and building die cast (including Trim Dies) & plastic injection molds. We are highly qualified and are ISO

Die Cast Tooling

We custom build die casting and injection tooling (including Trim Dies), used in the manufacture of metallic and non-metallic components. Our tooling division can make dies for components of varied sizes and materials. For instance, our tools have been used in the manufacture of products ranging from small plastic toys to heavy-duty military equipment. Die casting and injection tooling types that we manufacture include die cast molds, plastic injection molds, multi-cavity dies, and master unit dies (MUD). We build die cast tooling with single or multiple cavities for brass, zinc and aluminum castings. If required, we can offer trim tools for cast parts as well. Plastic injection molds are available with both conventional runner systems and hot runner systems. We make modular molds with built-in side action and complimentary tooling for over molds too. Our multi-cavity dies and master unit dies are suitable for both metal and plastic applications. M.U.D. units can be made with built-in unit holders in standard or specialty M.U.D. sizes. 2D and 3D CAD/CAM software packages, including SolidWorks and AutoCAD, are used to design dies in-house. While designing dies, our designers take into consideration all the operational factors of the dies. For example, tools used for high-volume production are designed factoring in longevity. Low-cost dies for prototyping or sample applications can be built in short time frames. Also, we can modify, troubleshoot, and repair your existing tools and dies. Provide your product design to our engineering department thru the use of the "RFI" Request for Information selection button. Simply attach your design and submit your request. We'll review your design and make contact with you prior to the generating a quote for your review.

-

Specifications

- Part Quantities

-

We have the ability to produce a low cost die for prototype purposes, or we can build a long lasting tool to support high production requirements. We can build you a high-grade tool that is capable several hundred thousand cycles or more.

Note: DACO does not perform any casting services, but only produces the tooling for that process.

- Tolerances

-

+/- 0.0005 for an average production run die, but not limited to.

We will produce a die to meet or exceed your design specification.

- Types of Tooling

-

Aluminum Die Cast Molds

Zinc Die cast Molds

Magnesium Die Cast Molds

Brass Die Cast Molds

Multi Cavity Dies

Regular / Heavy Duty Molds

- Tool Sizes

-

DACO Precision can create tooling for applications smaller than 1” x 1” x 1” up to large castings exceeding 3 feet in length or height.

The heaviest tool built to date was 30,000 pounds, though we are capable of larger dies.

- Applications

-

Common Aluminum Die Casted Products:

- Engine Blocks

- Housings

- Cylinder heads

- Pump Housings

- Engine Heads

- And Many Others

Common Zinc Die Casted Products:

- Electric Motor Casings

- Faucet Heads

- Handles

- Housings

- Zippers

Common Magnesium Die Casted Products:

- Automotive Parts

- Electronic Components

- Appliance Assemblies

- Power Tool Assemblies

Common Brass Die Casted Products:

- Pipe and Valve Fittings

- Decorative Handles

- Marine Products

- Medical Products

-

Capabilities

- Secondary Operations

-

Burnishing

Carbon and Graphite Electrodes

Chamfering

Cleaning

CNC Bar Work

CNC Drilling

CNC Machining

Counter Boring

Counter Sinking

Deburring

EDM Services wire and conventional

Grinding

Laser Cutting

Riveting

Spot Welding

Tapping

- Industries Served

-

Aerospace

Agriculture

Automotive

Construction

Electronics

Food and Service

Government

Industrial

Machinery

Marine

Military

Railroad and Mass Transit

Recreational Vehicle

- Client List

-

Mercury Racing

NordicWare

- Engineering/Design Software

-

Auto Cad

Bridgeport

PowerMILL

PowerSHAPE

Pro/Engineer

SDRC

Solid Works

- Engineering/Design Software

-

Auto Cad

Bridgeport

PowerMILL

PowerSHAPE

Pro/Engineer

SDRC

Solid Works

- Quality Certification

-

ISO 9001:2008 Certified

-

Equipment List:

- Equipment List

-

1-Mitsubishi Boring Bar

Model M-HT11/1416

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 78.7 inches

Y-travel 59.1 inches

Z-travel 51.2 inches

Spindle 4.3 inches

Diameter with Stroke 19.7 inches

Horsepower 30

Loading Capacity of table 15,400 lbs.

Renishaw Probe Systems1-Femco Horizontal Boring Mill

Model WBMC-100R2

Complete with Mitsubishi Meldas 520-M control and “B” axis

X-travel 79 inches

Y-travel 71 inches

Z-travel 67 inches

Spindle 4 inches

Diameter with Stroke 28 inches

Milling Spindle Diameter 8.86 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 62 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model MPA-V70C

X-travel 52 inches

Y-travel 27.5 inches

Vertical Z-axis 25.6 inches

Max/Min distance spindle to table 33 inches – 8 inches1-Mitsubishi Vertical Machining Center

Model M-V5B

X-travel 31.5 inches

Y-travel 20.1 inches1-Okada Graphite Electrode Machining Center

Model GM544

X-travel 19.7 inches

Y-travel 15.7 inches

Vertical Z-travel 11.8 inches

Spindle 30,000

Maximum RPM inches

Torit Vac System1-Mitsubishi CNC Vertical Machining Center

Model V-60E including all standard accessories and additional options1- Mitsubishi EX-8 CNC EDM

With PC Based 64 Bit Control and FPII 60 Power Supply

Work Tank Size: 30.3 x 19.6 x 9.8 inches

9.8 Ram Travel

1210 Maximum Work Piece Weight1- Mitsubishi EX-30 CMC EDM

With C11E Control and 16-Position Macro ATC

Deep Work Tank Size: 47 x 31.5 x 18 inches

Table Size: 35.88 x 26.77 inches

13.77 Ram Travel

4,410 lbs. Maximum Workpiece Weight

4.5 Grams per minute Metal Removal1- Chevalier Precision Tool Room Electrical Discharge Machine

Model: ED-252 50 AMP

3-Axis Futaba Digital Readout System

Tank: 30 x 20 x 10.6 inches1- Chevalier Precision Tool Room Electrical Discharge Machine

Model: DM-540 75 AMP

3-Axis Futaba Readout System

Tank: 51 x 29.5 x 20.7 inches1- Chevalier Fully Automatic Surface Grinder

Model: FSG-2060TC

Table Size: 21 x 62 inches

Maximum Grinding Length 60 inches

Maximum Grinding Width 20 inches

Maximum Distance from table to surface to Spindle Center Line 29.0 inches1-Chevalier Fully Automatic Precision Hydraulic Surface

Grinder Model: FSG-1632AD

Table Size: 15.75 x 31.5 inches

Maximum Grinding Length 32 inches

Maximum Grinding Width 16 inches

Maximum Distance from table to surface to Spindle Center Line 24.375 inches1-Chevalier Surface Grinder

Model: 618 High Precision2-Chevalier Surface Grinders

Model: 618M

Maximum Grinding Length 18 inches

Maximum Grinding Width 6 inches

Maximum Distance from table to surface to Spindle Center Line 18 inches

with Sony Digital Readouts1-Clausing/Metose Precision Lathe

Model: 1440 Bed 14 x 40 inches2-Bridgeport Series I Standard Mills

With Digital Readouts and Power Feed

Table travel x-axis 30 inches

Saddle travel y-axis 12 inches

Quill travel 5 inches

Knee travel z-axis 16 inches

Table size: 42 x 9 inches2-Clausing Vertical Milling Machines with Proto Trak MX2

- Secondary Operation Equipment

-

3/4 H.P. Delta Drill Press

Clausing 10 x 15 inches Automatic Wet Grinder, 1 x 12 inches Wheel

Harrig 6 x 12 inches Surface Grinder with 12 inches Electro Magnet

Wells 6 x 10 inches Cutoff Saw

Myford MG12 Grinder

2 – Boyer 6/12 Surface Grinder

Snow 3/8 inch Auto Tapping Machine

Brother BT-2-225 Auto Tapping Machine

Electra 6715 Auto Heat Treat And Draw Furnace

Wilson Model #4TT BB Hardness Tester

Wilson Model #HR 150A Hardness Tester

Yoder 10,000# 10 Ga. x 36 inches Wide Coil Slitting Line with Wean Over Arm/Coil Separator

10 Cubic Foot C&S Rapid Finish Deburring Machine with Auto Unload

10 Cubic Foot Rosler Automatic Heated Parts Drying Machine

10 Cubic Foot Sweco Rotary Deburring Machine

5 Cubic Foot Sweco Rotary Deburring Machine

Chicago Turret Self Feed Rivet Machine

Miller Portable Spot Welder

Miller Model #CP-200 Wire Feed Welder

A.O. Smith 350 Amp Welder

Craftsman #30-230 Portable Welder

Snapon Model #YA 3330 Portable Plasma Cutter

- Support Equipment

-

Japax LUX-3 Wire EDM, with 5.0 Bridgeport Easy Cam Software

Japax LXE Wire EDM, with 5.0 Bridgeport Easy Cam Software

Supermax 3 H.P. CNC 3-Axis Vertical Mill, Computer Programable, with Fixturing OR 6 inches Vise

ProtoTRAK K3S2 CNC Milling Machine With SM2 Control

ProtoTRAK K3 CNC Milling Machine With Edge Control

ProtoTRAK TRL 1440S CNC Lathe With SL Auto Control

Bridgeport 2 H.P. Milling Machine with Q.M.S Readout, 6 inches Vise

Excello 2 H.P. Ram Turret Milling Machine with TRAK 3 Position Readout, 6 inches Vise

Bridgeport 1 ½ inch H.P. Milling Machine with 6 inches Vise

Tech-Turn 13 inches Swing x 42 inches Lathe

Sullair 30 Hp Rotary Screw Air Compressor

Zeks Auto Air Drying System

25 H.P. Quincy Air Compressor with Aftercooler/Water Separator

15 H.P. Quincy Air Compressor with Aftercooler/Water Separator

5 H.P. Ingersol Rand Air Compressor

80 x 12 feet Die Racking System

Safety Kleen Parts Washer

Misc. Airfeeds, Uncoilers, And Straighteners

Misc. Master Dies, Inspection Equipment, Hand Tools, Tool Cutters, Tool Boxes, Etc.

Design, Build & Repair of Tooling

DACO can help and assist you with all tooling design, and construction on new and existing tooling, and offer part cost savings or over all tool cost saving options depending on the actual tool design. DACO can also help with all types of tooling and needed tooling repairs, including punch & die, core & cavity, locate and replace almost any components, and can completely reconstruct old or broken down tooling if needed.

Plastic Injection Tooling

DACO Precision is a top-quality manufacturer of plastic injection molds. We can design and construct die core inserts as well as complete plastic injection molds. For high output, we can build a multi-cavity mold so our customers can cast multiple parts at once. Using the latest software, we are able to effectively design and build a tool from 2-D and 3-D part prints. DACO can build complex molds that require moving slides, lifters, and over-molding. To build a long-lasting quality die, DACO insists on using high quality, certified materials when constructing any tooling. Our tooling technicians work very hard to provide customers with a high-performing, quality mold that will run thousands of high quality parts. DACO has many years of experience in designing and building die cast & plastic injection molds. We are highly qualified and are ISO 9000:2008 certified.

Multi-Cavity Tooling

DACO Precision keeps the customer’s needs in mind. If a high-output tool is required, we would suggest a multi-cavity tool. This particular type of mold has multiple chambers, which allows casters (or injectors) to produce multiple parts each cycle. We have the machinery and the people to create a smooth running multi-cavity mold. To build a long-lasting quality die, DACO insists on using high quality, certified materials when constructing any tooling. Our tooling technicians work very hard to provide customers with a high-performing, quality mold that will run thousands of high quality parts. DACO has many years of experience in designing and building die cast & plastic injection molds. We are highly qualified and are ISO 9000:2008 certified.

Tooling Revisions & Updates

DACO Precision provides repair, maintenance, and adjustment services for die cast (including Trim Dies), and plastic injection molds. Whether it be a small fix or a full overhaul, DACO should be able to turn your existing tool into a high performance quality mold. To make sure the repair/adjustment will perform and will be long-lasting, DACO insists on using high quality, certified materials when constructing any tooling. Our tooling technicians work very hard to provide customers with a high-performing, quality mold that will run thousands of high quality parts. DACO has many years of experience in designing and building die cast (including Trim Dies) & plastic injection molds. We are highly qualified and are ISO 9000:2008 certified. Provide your product design to our engineering department thru the use of the "RFI" Request for Information selection button. Simply attach your design and submit your request. We'll review your design and make contact with you prior to the generating a quote for your review.